Pencils are one of the most commonly used writing tools in the world, with millions of them produced and used every day. Despite their widespread use, many people do not know how are pencils made.

By understanding how pencils are made, we can appreciate the intricate details that go into creating this humble but essential tool. So, if you’re curious about the art and science behind the pencil, let’s delve deeper into the manufacturing process to discover how are pencils made.

1. Structure of pencil

How are pencils made? The structure of a pencil may vary slightly depending on the specific type or brand of pencil. For example, some pencils may have different types of wood casing, different shapes or sizes of graphite core, or no eraser at all. However, these three components are the basic building blocks of most standard pencils.

1.1 Shell

How are pencils made? Regarding the selection of wood pencils, most manufacturers will choose basswood. Basswood wood is fine-grained, tough, and easy to work with. It is widely used in the production of wooden crafts. There are a few factories that use willow wood. This wood is used to make high-grade pencils.

A common type of plastic pencil is the bendable pencil. In addition to its writing function, this pencil can be twisted and bent into many shapes, and you can even tie it into a knot. Don’t worry about your bendable pencil being broken or snapped.

Paper pencils, also known as eco-friendly pencils, use waste paper as raw material. This practice saves wood, protects forests, and enables environmental reuse. However, there is no obvious advantage of paper pencils over traditional wooden pencil sticks in terms of production cost. There is no significant difference in the user experience, so it is not widely promoted at present.

1.2 Pencil lead

How are pencils made? Let’s take a look at pencil cores. Pencil cores are made of graphite and clay in a certain ratio. Graphite is solid with a metallic luster composed of carbon, which has a very stable structure and cannot be easily destroyed. The main function of clay is to increase the hardness of the refill. We usually use H to indicate the content of clay and B to indicate the content of graphite.

In the national standard, pencil cores can be divided into 18 types according to the different concentrations of graphite. the larger the value in front of H, the harder the pencil is. That is, the greater the proportion of clay, the lighter the color. b represents the graphite content, which is used to indicate the softness of the pencil core and the shade of the writing. The higher the value, the softer the texture and the darker the color.

1.3 Eraser

The raw eraser materials are rubber or plastic, sulfur, plant oil, and gravel.

Pencils with erasers are also very common nowadays, mainly for the convenience of people who don’t use pencils very often. However, most pencils come with erasers that are relatively ineffective. Because plastic erasers are soft, if they are made into small cylindrical shapes, they can easily break off in the middle when they are used. So people prefer to use the softer rubber eraser than the pencil that comes with the eraser.

2. Wood is commonly used for pencils

How are pencils made? The most important part of a pencil is the pencil lead, followed by the wood it is made of. The difference in the wood affects the performance of the whole pencil. When making pencils, the choice of wood is very important. The basic requirements are straight grain, detailed and uniform structure, slightly soft texture, slightly brittle, no deformation, etc. At present, the main woods chosen for pencils are poplar, basswood, incense cedar, red cedar, pine, spruce, etc.

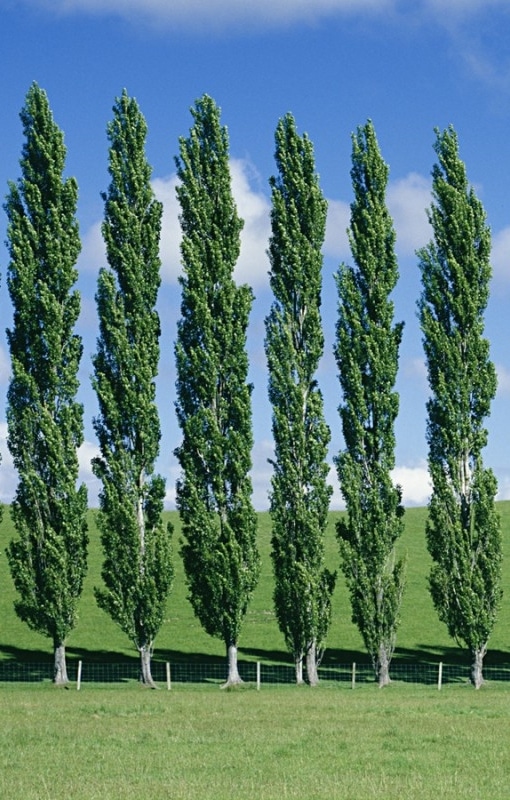

2.1 Poplar

Poplar is a popular material for pencil production due to its availability, affordability, and desirable properties for writing instruments. Poplar is a hardwood tree that grows quickly and can be found in many regions around the world. The wood of the poplar tree is lightweight, soft, and uniform in texture, which makes it easy to work with and ideal for pencil production.

One of the main advantages of poplar as a pencil material is its affordability. Poplar wood is relatively inexpensive compared to other pencil woods like cedar or spruce, which makes it a popular choice for budget or promotional pencils.

2.2 Basswood

Basswood is found in large quantities in Europe, North America, and Asia. Basswood is a wood commonly used by Chinese pencil makers. Basswood is an excellent material for making pencils. It is wear and corrosion-resistant and does not crack easily. It has a fine grain, is easy to work with, is tough, and has a relatively wide range of applications.

2.3 Incense cedar

Incense cedar is one of the most common types of wood used in pencils. It is a softwood and comes from western North America and Asia. Incense-cedar has several advantages over other woods.

First, because of its soft nature, the wood can be easily cut without forming any splinters. Second, it is very light, so it does not add unnecessary weight to the pencil. Third, it feels comfortable in the hand when sharpening pencils. Fourth, it has a pleasant scent that is pleasant to the senses.

2.4 Red cedar

Red cedar is a wood that grows in the eastern and southern United States. It is typically chosen for the production of traditional pencils. It is reddish-brown, has a low shrinkage rate, is light in weight, and is hard.

It is a durable hardwood and is the material of choice for traditional American pencils. It has a strong odor, however, which can be unpleasant. However, red cedar was gradually replaced by California incense cedar when the market was dominated by cheap pencils.

2.5 Pine

Pine is a softwood that is sometimes used as a material for pencil production. Pine wood has a light color and a fine, uniform texture with straight grains. The wood is lightweight and easy to work with, making it a popular choice for many applications, including furniture, construction, and paper products.

2.6 Spruce

Spruce wood is a harder wood that is used for making high-quality pencils, such as artist pencils.

The choice of wood can affect the quality and performance of a pencil, as well as its appearance and cost. Cedar is generally considered the best wood for high-quality pencils, while basswood is a popular choice for everyday use.

| Wood Species | Density (lb/ft3) | Hardness | Grain Texture | Sharpening Ease | Durability |

|---|---|---|---|---|---|

| Poplar | 20-30 | Soft | Medium | Moderate | Moderate |

| Basswood | 19-23 | Soft | Fine | Easy | Low |

| Incense cedar | 23-34 | Soft | Fine | Easy | High |

| Red cedar | 22-31 | Soft | Fine | Easy | High |

| Pine | 22-31 | Soft | Coarse | Moderate | Low |

| Spruce | 20-30 | Hard | Fine | Difficult | High |

- Density: Higher density generally indicates a stronger and more durable wood, but it also means the pencil will be heavier.

- Hardness: A harder wood will produce a pencil with a harder lead, which can be good for fine detail work or for darker lines. Softer woods will produce a pencil with a softer lead, which can be good for shading and blending.

- Grain texture: The texture of the wood grain can affect the appearance of the pencil, as well as the ease of sharpening.

- Sharpening ease: Some woods are easier to sharpen than others, which can affect the user experience.

- Durability: A more durable wood will produce a pencil that is less likely to break or split, and may last longer. However, more durable woods can also be more expensive.

3. The process of making pencils

Next is the focus of this article, how are pencils made?

The process of making a pencil is actually quite fascinating, involving a combination of natural materials, advanced machinery, and skilled craftsmanship. From the selection of the wood to the formulation of the graphite core, each step in the pencil-making process is carefully controlled to ensure that the final product is of the highest quality.

If you want to know about the process of making colored pencils, you can click here: What Are Colored Pencils Made Of?

Here’s a general overview of how are pencils made:

3.1 Making lead

Mixing the graphite core: Graphite, clay, and water are mixed together to create a paste that will form the core of the pencil. The proportion of graphite to clay determines the hardness of the core.

Extruding the core: The graphite core is extruded through a machine that shapes it into a long, thin cylinder.

Drying and cutting the core: The extruded core is dried in an oven and then cut into individual pencil-length pieces.

3.2 Assembled with the wood

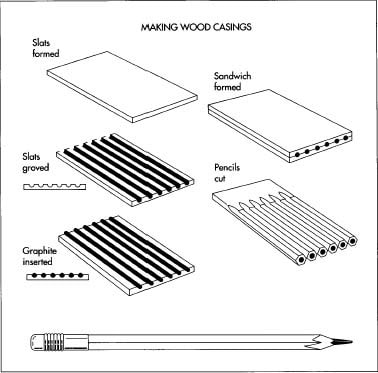

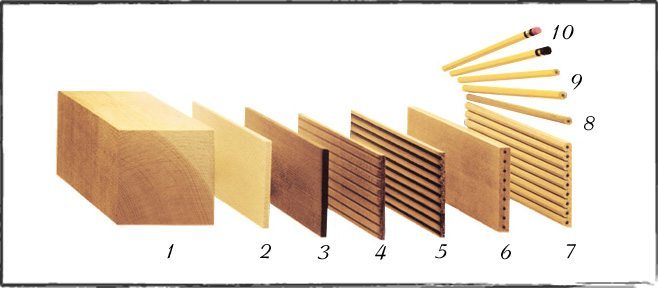

Preparing the wood: Pencil wood is cut into slats, which are then kiln-dried to remove moisture and prevent warping. The average length of a pencil is about 19 cm.

Gluing the core and wood: Then use the machine to carve a semi-circular groove in each board and fill it with glue. The graphite lead core is then placed and covered with another board with the semicircular grooves already carved. The two are tightly joined and squeezed by the machine until the glue is completely dry.

Cutting shape: Then it can be cut into the desired shape, which is usually hexagonal. Six to nine pencils can be cut out of a single board.

There are many kinds of pencil shapes. If you want to know more, please click here: Shape Of Pencil: The Ultimate Guide.

3.3 Additional requirements

Applying the finish: The pencils are then coated with a lacquer finish to give them a smooth surface. If you need a colored shell, you can also choose a good color and spray it.

Applying the eraser: Attach the ferrule (round metal housing) to the top end of the pencil with glue and insert the eraser. A pencil with an eraser is complete.

Sharpen: When you buy pencils, some of them are already sharpened. This is because the manufacturing process uses a special machine to sharpen the pencil using rollers and abrasive belts.

3.4 Quality control

Each pencil is inspected for defects, and any defective pencils are removed from the batch. And The pencils need to be randomly inspected after they are made. The inspection items are hardness check and durability check.

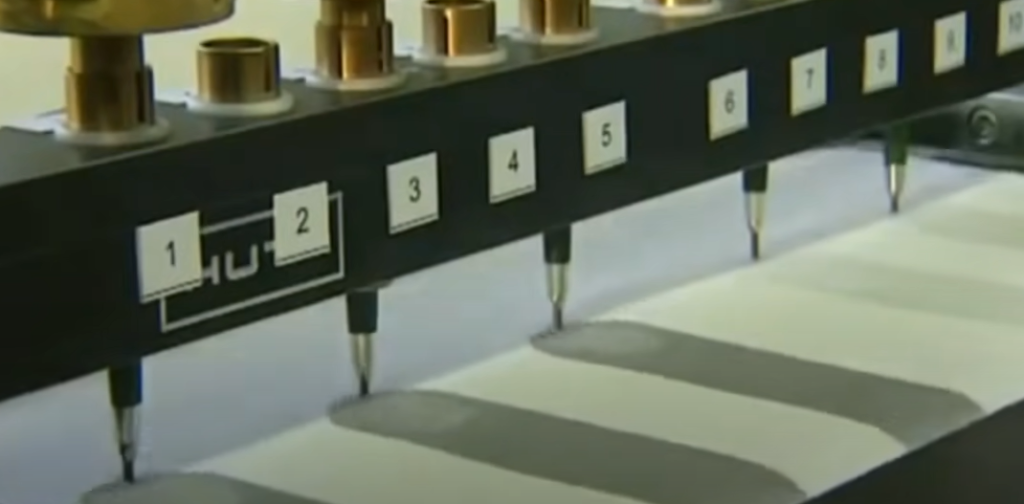

The hardness check, also called the Wolff-Wilborn test, uses graphite pencils with different hardness values to assess the hardness of the coating. The test consists of pushing the pencil through the layer at a fixed 45-degree angle under a constant force. The hardness of the coating is determined by the resulting marks.

For durability check, fix a pencil on the machine and then draw circles on the paper to test its durability.

3.5 Packaging

After a simple inspection by the staff, the product is packaged as required. Pencil packaging is important to prevent pencils from being damaged during transportation.

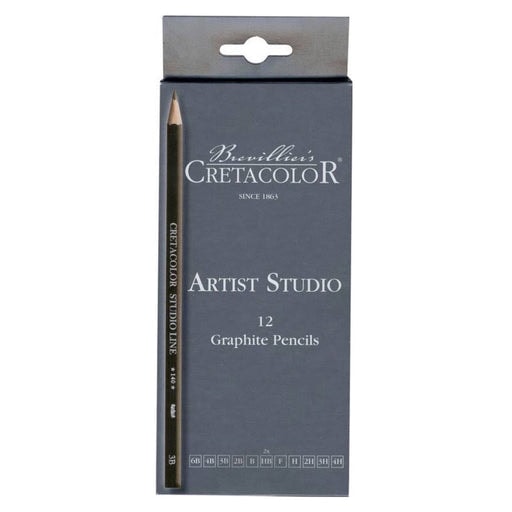

The choice of packaging method will depend on the intended use and target market for the pencils. Higher-end or artist-quality pencils may be packaged in more premium packaging, while budget or promotional pencils may be sold in simpler packaging to reduce costs.

There are several common packaging methods for pencils, including:

Individual pencils: This is the simplest packaging method, where each pencil is sold individually without any additional packaging. This is often used for higher-end or artist-quality pencils.

Sets of pencils: Pencils are often sold in sets of varying sizes, ranging from small sets of 6-12 pencils to large sets of 72 or more. These sets are typically packaged in a cardboard box or tin and may include additional accessories such as erasers or sharpeners.

Blister packs: Pencils can also be packaged in clear plastic blister packs, which provide a clear view of the pencils while also protecting them from damage. Blister packs are commonly used for promotional or budget pencils.

Tubes: Pencils can be packaged in tubes made of cardboard, plastic, or metal. These tubes are often used for high-end or artist-quality pencils and can provide additional protection and portability.

Display boxes: Pencils can be packaged in display boxes for retail purposes, which can include branding and marketing information. These boxes are often made of cardboard or plastic and may include a variety of pencil sizes and types.

| Packaging Method | Description | ADVANTAGES | DISADVANTAGES |

|---|---|---|---|

| Individual pencils | Each pencil is sold individually without any additional packaging | Low cost, easy to use | Not suitable for sets or gifts, limited protection |

| Sets of pencils | Pencils are sold in sets of varying sizes, typically packaged in a cardboard box or tin | Convenient, good for gifts, and includes accessories | Limited protection, can be bulky |

| Blister packs | Pencils are packaged in clear plastic blister packs | Provides protection, easy-to-see contents | Limited branding options, can be difficult to open |

| Tubes | Pencils are packaged in tubes made of cardboard, plastic, or metal | Provides protection, easy to transport | Limited branding options, can be expensive |

| Display boxes | Pencils are packaged in display boxes for retail purposes | Provides branding and marketing opportunities, can display a variety of sizes and types | Can be expensive, and may not provide much protection |

- Advantages and disadvantages are subjective and may vary based on the intended use and target market for the pencils.

- Other factors such as environmental impact, sustainability, and production cost may also influence the choice of packaging method.

4. Summary

The production of a pencil generally requires 20 to 50 processes. This places high demands on a manufacturer’s quality control management capabilities. Finding a pencil supplier like Honeyoung can make your purchase more secure and easier.

How are pencils made? Making a pencil is not easy. Many objects around us that look ordinary have often undergone many hours of building and refining. Please don’t throw them away before you finish using them. The pencil production process at Honeyoung is always concerned with environmental issues and reducing material waste and pollution during production. Honeyoung pencils are at the forefront of the industry.

If you want to know more pencil brands, click here: Top 10 Pencil Brands In The World